Add to Cart

1. Technical parameter

| No. | Item | Unit | Value |

| 1 | Maximum thickness of plate | mm | 16 |

| 2 | Maximum width of plate | mm | 3000 |

| 3 | Yielding limit sheet metal | º | 245 |

| 4 | Loaded with minimum coil diameter | mm | Φ800 |

| 5 | Bending roll speed | m/min | 4 |

| 6 | Two bottomroller center distance | mm | 430 |

| 7 | Upper roller diameter | mm | 340 |

| 8 | Bottom roller diameter | mm | 260 |

| 9 | Motor power | KW | 18.5 |

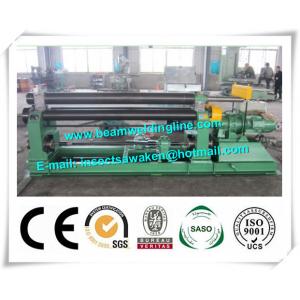

2. Description of structure

The machine adopts 3-roller symmetrical structure with the upper roller moving vertically in the center between the two lower rollers, which is achieved through the drive of the screw, the nut, the worm and the lead screw, the two lower rollers, and provides the plate materials with torque through the engagement of the output gear of the moderator with the fear of the lower rollers. The machine is the overall structure, the working section and the main transmission section are all installed on a rigid welding base. It is convenient to installation and adjustment.